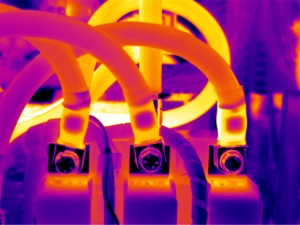

Successful companies sometime take for granted the electrical systems that support the backbone of their operations. And once one of those systems hits a glitch, the whole business can be exposed to a potentially hazardous situation or costly repair.

That’s why there’s a need for facilities to perform regular maintenance on their electrical systems. Electrical Preventive Maintenance (EPM) is the practice of implementing routine and recurring maintenance procedures to prevent damage or malfunction to electrical connections and electrical distribution system equipment.

As an experienced EPM contractor, Harrington Electric Co. offers “EPM+,” a proactive preventive maintenance service designed to ensure the reliability and safety of a facility’s electrical system. This service can ensure electrical system integrity through routine testing and maintaining the operation’s electrical distribution equipment.

A thorough EPM service can preserve and protect your operation in five key areas, resulting in various cost savings, increased safety and decreased management risks.