Harrington Electric Co.’s EPM+ service is proactive Electrical Preventive Maintenance to ensure the reliability and safety of a facility’s electrical system.

Electrical system integrity is achieved by routinely testing and maintaining the electrical distribution equipment.

Electrical problems cannot be observed visually – therefore we utilize the following methodologies to maintain system integrity:

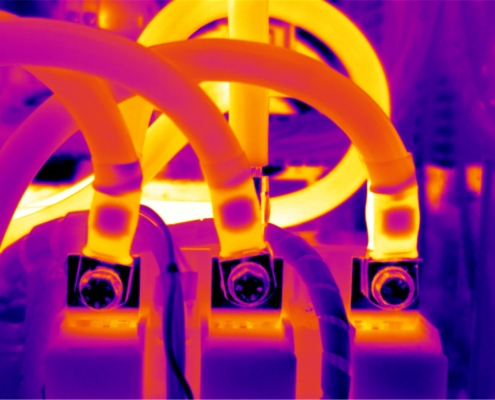

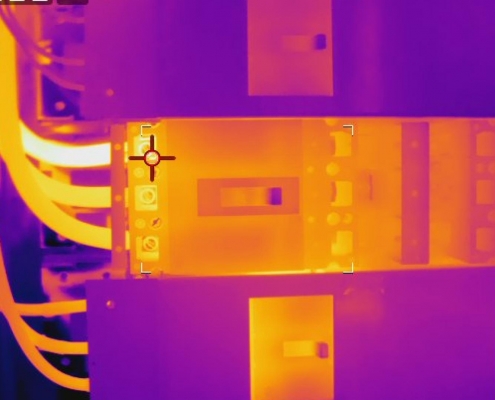

Infrared Thermography

To identify hot spots of operation, usually due to poor connections or high ampacity.

Megger Testing

Of distribution equipment, motors, and feeder cables.

Hi-Pot Testing

To confirm the insulation integrity of medium voltage equipment and cables (when appropriate).

Ductor Testing

Contact resistance testing of electrical contacts (at circuit breakers, switches, and starters).

Ultra-Sonic Testing

To search for tracking (to identify and mitigate possible fault paths).

Circuit Breaker Testing

Both primary and secondary current injection.

Transformer Turns-Ratio

To track the integrity of transformer windings.

Transformer Oil Sample Testing

To monitor the dielectric strength and chemical stability of the transformer coolant.