Silencing the Demand for More Power

Harrington Electric Co. Modernizes Allied Witan’s Electrical Infrastructure

Harrington Electric Co. Modernizes Allied Witan’s Electrical Infrastructure

Allied Witan Company (also widely recognized as Alwitco®), located at 13805 Progress Parkway in North Royalton, Ohio manufactures industrial noise control devices which promote clean and quiet pneumatic operations. Their product lines – including Atomuffler® and Bantam® mufflers, air filters, and porous metal products – are designed to enhance health and safety in industrial settings. These products effectively reduce excessive noise from air exhausts of pneumatic equipment, contributing to a safer and more pleasant work environment. The company targets industrial clients seeking reliable solutions for noise control and efficient air management.

The original noise reduction idea started in the mid-to-late 1940s from the experiences of a newly-minted engineer who, as part of his new job, was going into many of the dangerously noisy Cleveland-area factories which were using the then-new pneumatic power. The first Atomufflers were born in the small family home basement in Cleveland. One thing led to another, and with the help from many terrific people along the way, that humble idea grew to a world-wide presence!

– As reported in the Royalton Recorder, 7/10/25

The 75-year-old company manufactures industrial mufflers, silencers and other specialized industrial noise control devices which promote clean and quiet pneumatic operations. (See side article.)

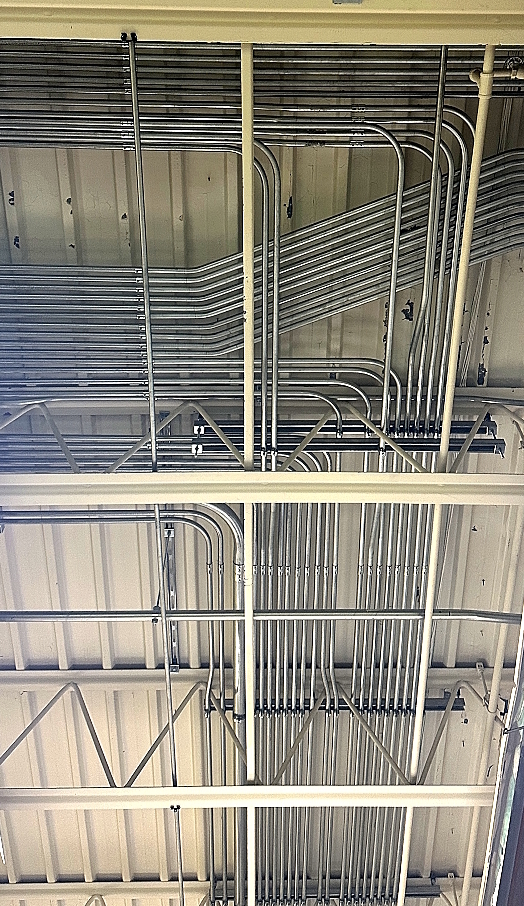

The frequent power losses and tripping breakers were symptoms of a deeper problem. “Over the years, we kept adding machines, lights, outlets—whatever we needed at the time. Eventually, it was just a jumble of conduit and wires,” said company president Sandy Nemeth. “We were trying to improve air conditioning and ventilation, and add new production equipment, but we didn’t have the capacity to support it.”

Allied Witan needed more than just a quick fix—they needed a complete electrical overhaul.

Harrington Electric Co. had been working with Allied Witan since 2019 when the company completed a facility-wide LED lighting retrofit project to replace the facility’s obsolete fluorescent systems. The improved lighting reduced both energy use and maintenance costs while enhancing employee comfort.

In 2023, when the company began planning for major equipment and building comfort upgrades, Brian Robinette, Harrington’s vice president of service, stepped in to assess the building’s electrical readiness. What he found confirmed Sandy Nemeth’s concerns: the system wasn’t just underpowered—it was dangerously outdated.

The electrical upgrade began in mid-2024 and took about a year and a half, carefully planned around Allied Witan’s busy production schedule. With the help of a dedicated crew—Pat Liscoe, Rich Drumm, Albert Madson, Bryan Croucher, and others—Harrington developed and executed a comprehensive plan to modernize the entire building without disrupting daily operations.

The modernization work included:

Utility coordination was a critical part of the process. The local utility provider, CEI, required the installation of a new pole, transformers, and inspection cans before service could be upgraded. After months of planning, acquiring all the necessary equipment, and preparation work inside the building, the utility upgrade and the three-phase cutover was scheduled during a normal week-long plant shutdown in July 2024. Bad storms elsewhere pulled off CEI workers from the project, delaying their portion a few days, but with all the solid preparation work, the Harrington team persevered to help the client.

The single-phase portion of the project started up a few months later, after a period of of planning, acquiring necessary equipment, and preparation work throughout the building. “We had to orchestrate the final cutover in conjunction with a brief scheduled shutdown of Allied Witan’s operation,” said Robinette. “We prepped everything in advance, then worked Friday through Sunday to switch over without disrupting any operations. By Monday, everything was up and running.”

A System Built to Scale

In addition to solving long-standing power issues, the new infrastructure provides room to grow. The building is now fully up to code, and the newly installed systems support both current operations and future expansion. Harrington Electric’s design also increased the number of switch bays, giving Allied Witan the flexibility to install new equipment without reconfiguring their power layout.

Looking back on what seemed like a lengthy, highly involved project, Sandy Nemeth described the complexity of the modernization job and working with a variety of contractors at the same time, including the Harrington team, HVAC contractors, and the utility crews. “There were so many variables involved in this project—CEI delays, storms, timing with our shutdown—but the Harrington crew worked hard and managed it all. Yes, of course it was a bit stressful at times, but it could have been so much worse. They kept all the work steadily moving along,” she said.

The project was more than just a renovation—it was a reinvention. “We’ve removed all the guesswork in our facility. There are no hot spots. Everything is logical, clean and clearly labeled. We’re ready for whatever’s next,” Sandy added.

Advice for Facility Owners

Brian Robinette emphasized that aging infrastructure can’t be ignored. “If your building is over 40 or 50 years old and you’re constantly reacting to small electrical issues, it’s time to think ahead and consider modernizing your facility. Our job is to facilitate your needs, work around your operations, and get you to a place where your facility is safe, efficient and scalable.”

Sandy agrees: “If you’re planning to grow, or even just keep the lights on without stress, get ahead of it. Harrington helped us do that—and I’d highly recommend them.”

Partnership with Ohio Energy Management Yields Big Savings for Harrington C...

Partnership with Ohio Energy Management Yields Big Savings for Harrington C...